Maintaining the integrity of cold chain solutions is essential for industries that rely on precise temperature control, such as food, pharmaceuticals, and vaccines. Temperature fluctuations during transportation or storage can result in spoiled products, regulatory compliance issues, and costly financial losses. To prevent these risks, businesses are turning to temperature and data loggers as critical tools for monitoring environmental conditions in real-time, ensuring product quality, and avoiding disruptions in the cold chain.

This article will explore how temperature and data loggers improve cold chain efficiency, their key features and benefits, and their applications across various industries.

This article will explore how temperature and data loggers improve cold chain efficiency, their key features and benefits, and their applications across various industries.

Why Temperature and Data Loggers Are Essential for Cold Chain Efficiency

Temperature and data loggers offer continuous monitoring and accurate temperature tracking throughout the cold chain. These devices record environmental conditions such as temperature and humidity, providing businesses with valuable insights into any deviations that might compromise product integrity. By monitoring temperature fluctuations in real-time, companies can take immediate corrective action if needed, preventing the risk of spoilage or contamination.

The ability to track data continuously also helps improve operational efficiency. Businesses can use the logger data to identify potential problem areas within the cold chain. For example, if specific routes or storage facilities are prone to temperature excursions, adjustments can be made to mitigate risks. This real-time monitoring ensures that temperature-sensitive products remain within the required temperature range throughout transportation and storage, minimizing the potential for spoilage or regulatory violations.

Moreover, logger data can be used for reporting and compliance purposes. Regulatory agencies often require documentation to verify that proper temperature control measures were maintained.

Moreover, logger data can be used for reporting and compliance purposes. Regulatory agencies often require documentation to verify that proper temperature control measures were maintained.

Features and Benefits of Advanced Data Loggers

Modern temperature and data loggers offer various advanced features that make them indispensable for cold chain management. Some of the key features include:- Wireless Communication: Many data loggers have wireless connectivity, allowing real-time data transmission to a centralized platform. This enables logistics managers to monitor temperature data remotely and receive alerts in the event of any anomalies.

- Cloud-Based Storage: Cloud-based solutions provide a secure and easily accessible repository for all temperature data. This ensures critical information is always available for audits, compliance checks, or internal reviews.

- Long Battery Life: Cold chain shipments often require long transit times, making battery life a crucial consideration. Modern data loggers offer extended battery life, ensuring temperature tracking continues uninterrupted throughout the journey.

The combination of these features allows data loggers to record and transmit critical data in real-time, allowing businesses to respond to potential issues as soon as they arise. This proactive approach helps reduce the risk of product loss, improve customer satisfaction, and ensure regulatory compliance.

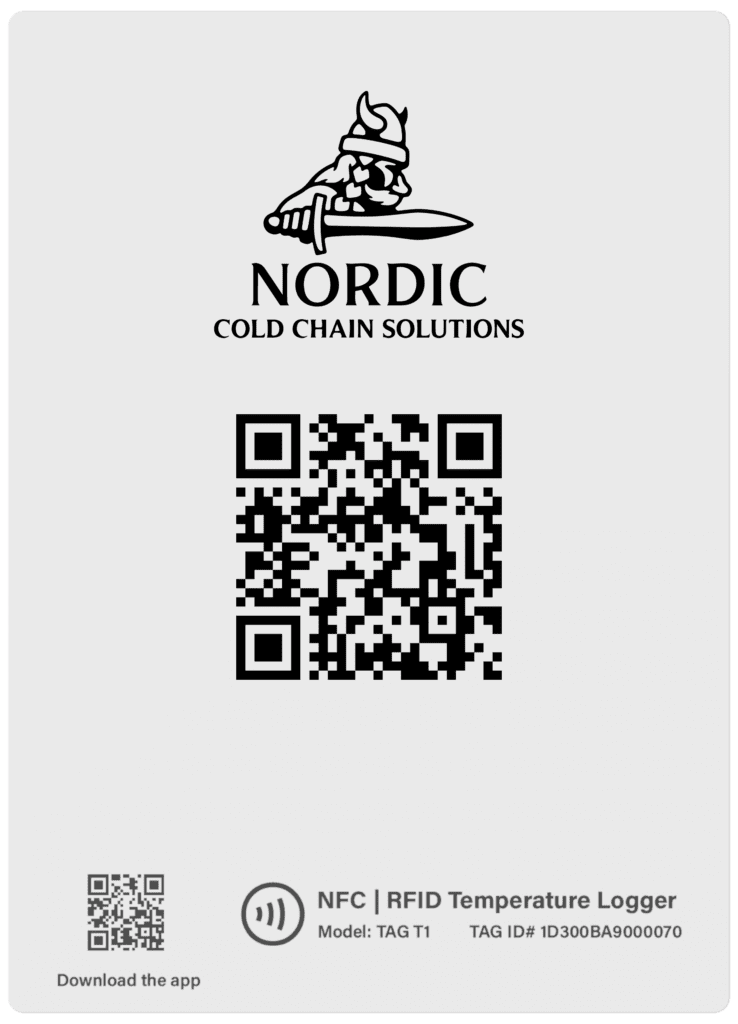

Nordic Cold Chain Solutions offers a range of advanced temperature and data loggers designed to meet the specific needs of cold chain logistics. Our loggers provide accurate and reliable data tracking, making it easier for businesses to ensure the safety and quality of their products.

Nordic Cold Chain Solutions offers a range of advanced temperature and data loggers designed to meet the specific needs of cold chain logistics. Our loggers provide accurate and reliable data tracking, making it easier for businesses to ensure the safety and quality of their products.

Applications in Various Industries

Temperature and data loggers are used across various industries to maintain the integrity of temperature-sensitive products. Here are a few examples of how different sectors benefit from their use:- Pharmaceuticals: The pharmaceutical industry often deals with sensitive products to temperature changes. Medications, vaccines, and biologics must remain within a specific temperature range to maintain their efficacy. Data loggers ensure that these products are kept within the required temperature thresholds throughout the supply chain, from production to delivery, safeguarding public health.

- Frozen Foods: Maintaining a strict cold chain in the frozen food industry is crucial to prevent spoilage and ensure that products arrive fresh at their destination. Temperature loggers monitor conditions throughout the transportation process, providing data to confirm that the cold chain was maintained from the warehouse to the retailer.

- Vaccines: Many vaccines are also temperature-sensitive and can degrade if exposed to the wrong conditions. Data loggers allow companies to ensure safe handling and compliance with international shipping regulations.

Using temperature loggers, these industries can maintain regulatory compliance, reduce the risk of product spoilage, and streamline their cold chain operations.

Choosing the Right Logger for Your Needs

When selecting a temperature and data logger for your cold chain operations, several factors must be considered, including the type of products you are shipping, the required temperature range, and the length of transit. For example, extremely temperature-sensitive products, such as vaccines or biological samples, may require loggers with more frequent data intervals and highly accurate sensors.Nordic Cold Chain Solutions provides a variety of temperature and data loggers to suit the specific needs of different industries. Whether you’re shipping frozen foods, pharmaceuticals, or vaccines, we offer state-of-the-art solutions to ensure your cold chain runs smoothly.

Closing Thoughts on Temperature and Data Loggers

Incorporating temperature and data loggers into your cold chain operations is essential for ensuring consistent quality and safety. These devices can provide real-time monitoring and accurate data tracking, enabling businesses to improve operational efficiency, reduce the risk of product spoilage, and ensure compliance with industry regulations.