Need to transport food, vaccines, or other temperature-sensitive items in a way that ensures they remain safe and within the required parameters? Chances are you’ve heard of the cold chain—a network of storage and transport solutions dedicated to safely delivering products that require controlled-temperature handling. In this article, we will explain exactly what constitutes a cold chain solution and why it is so important for ensuring product safety.

What Is the Cold Chain?

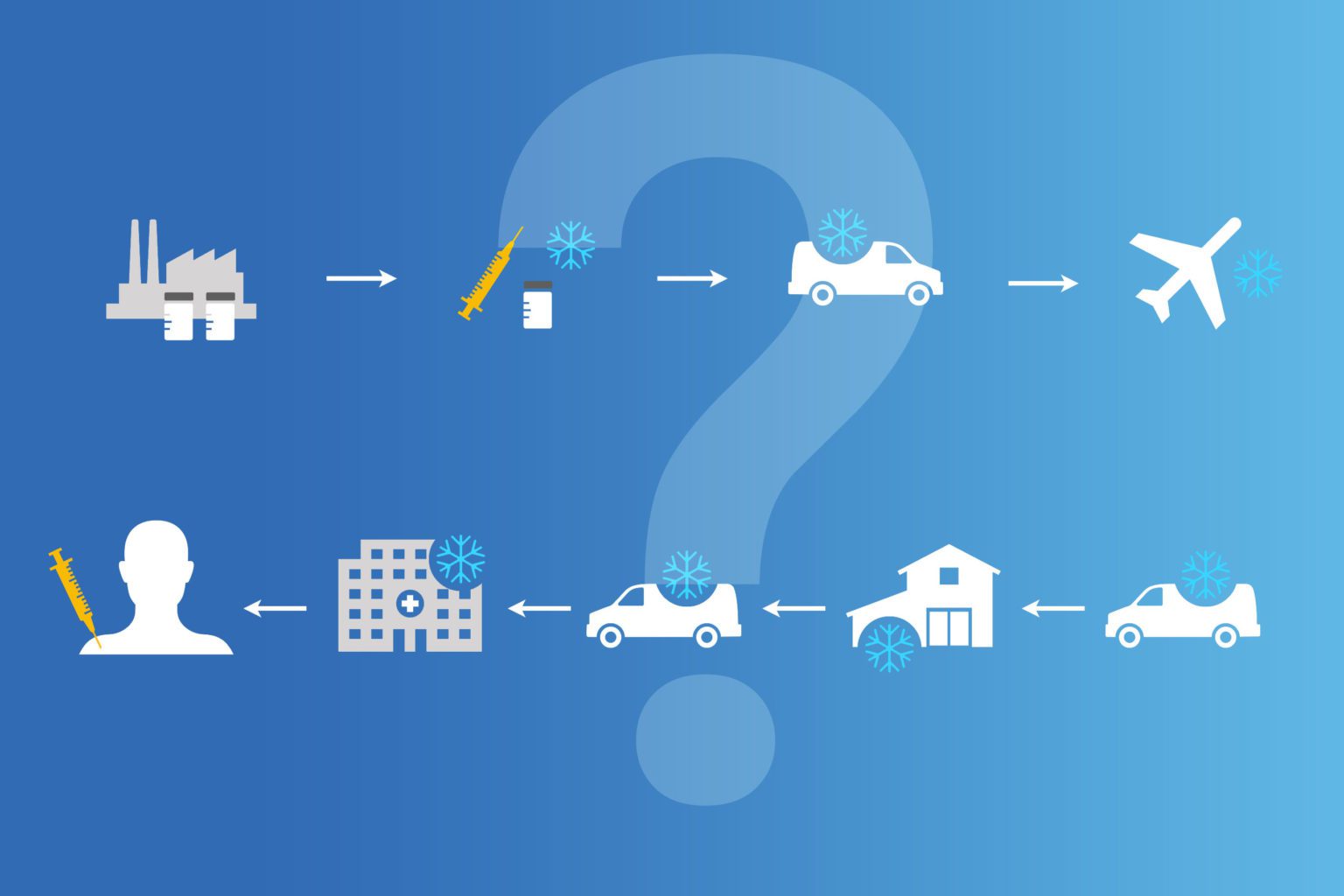

The Cold Chain is a temperature-controlled supply chain that encompasses the production, transportation, and storage of perishable goods. This type of logistics system works to maintain the quality and safety of food, pharmaceuticals, chemicals, and other items that are sensitive to environmental conditions such as heat or cold.

The Cold Chain has become increasingly important with the growing global demand for fresh food products, medicines, and vaccines. It helps ensure that these items reach their destinations in optimal condition with minimal spoilage or degradation due to poor storage conditions.

Temperature Is Important

Temperature control is an essential part of keeping goods safe during transport across long distances. Temperature-sensitive items require a careful combination of insulation materials (such as foam panels) packaged in specialized containers designed for maintaining temperature ranges from -50°C to +80°C. These containers can be fitted with thermometers or other sensors which allow users to monitor temperatures throughout transit via real-time data tracking.

Proper Packaging

Other methods employed in the Cold Chain include proper packaging techniques such as shrink wrapping; bundling; labeling; cross-packing; cushioning; palletizing; storage design/layout optimization etc., which all serve different purposes depending on the type of product being transported. All these processes can help reduce product loss resulting from shipping damage, theft, or mishandling due to manual labor operations, etc., thereby providing consistent quality control measures throughout the entire life cycle from manufacturing through distribution until delivery at the customer end.

Transportation

Refrigerated trucks are used for transporting chilled goods over longer distances while insulated vans/trucks may be used for shorter journeys when cold air conditioning is needed but not refrigeration ramps (coolers). The latest innovations make use of a variety of technology such as GPS tracking systems, RFID tags, special software programs, etc. Altogether making up what is called “smart” logistics which optimizes route planning, inventory management & traceability thus helping meet stringent customer needs & regulatory requirements ensuring timely delivery & high service levels.

Everyday Items That Require Cold Chain

Cold chain refers to the process of maintaining a specific temperature range throughout the entire supply chain for products that require controlled temperatures for safe storage and transportation. Everyday items that require cold chain are typically food products, pharmaceuticals, and medical supplies.

Food Products: Foods such as ice cream, milk, and dairy products, seafood like fish or shellfish, and frozen prepared meals such as pizzas or dinners that require reheating before consumption all must maintain certain temperature ranges during their journey from the production facility to store shelves. Without proper refrigeration temperatures being maintained all along the way these foods can become contaminated with harmful bacteria leading to food-borne illness in consumers who unknowingly consume them.

Pharmaceuticals: Medications such as vaccines or treatments containing sensitive active ingredients need cold chains to ensure they retain their stability and effectiveness at room temperature until consumed by patients. Particularly if those medications are meant for pediatric use then the utmost care is taken in storing them in ideal conditions using multiple layers of insulation material through shipment stages so that they can reach their final destination safely without any degradation of their properties due to changes in environmental conditions.

Medical Supplies: For medical supplies such as organs destined for transplantation or stem cells used during experimental treatments keeping these items at an optimal temperature while they travel from one place to another is essential since a change in even a few degrees could mean permanent damage and be fatal for humans receiving them once transplanted into their bodies. It’s therefore important that extreme caution be taken when transporting blood samples across long distances so as not to compromise on quality assurance standards expected by healthcare providers around the world when dealing with lifesaving interventions like organ transplantation or gene therapy.

For more information on products that require cold chain, check out our article What Types of Products Require Cold Chain?

The Role of Packaging in the Cold Chain

The role of packaging in the cold chain is of critical importance. Cold chain logistics ensure that products such as food, pharmaceuticals, and medical supplies are maintained at a specified temperature while they are shipped and stored. To meet those requirements, it’s essential that the right type of packaging be used in order to protect the product from environmental conditions like extreme temperatures or humidity levels.

Packaging must be able to contain any thermal energy introduced into it by ambient sources, while also protecting its contents from outside influences. It must also be durable enough to resist physical shock caused by handling and transportation processes as well as tampering and theft prevention measures like seals or locking systems. Furthermore, special containers can provide greater product protection against UV light and oxygen exposure than traditional materials like corrugated cardboard boxes or paper-based wraps often used for food items since these types provide inadequate protection from ultraviolet rays which may cause degradation due to photo-oxidation or insect infestation during storage periods over long distances.

Packaging must be able to contain any thermal energy introduced into it by ambient sources, while also protecting its contents from outside influences. It must also be durable enough to resist physical shock caused by handling and transportation processes as well as tampering and theft prevention measures like seals or locking systems. Furthermore, special containers can provide greater product protection against UV light and oxygen exposure than traditional materials like corrugated cardboard boxes or paper-based wraps often used for food items since these types provide inadequate protection from ultraviolet rays which may cause degradation due to photo-oxidation or insect infestation during storage periods over long distances.

In addition to the physical properties provided by proper packaging selection, there are other aspects that require consideration when selecting an ideal cold chain container including material selection according to transport regulations, compatibility with varied shipping methods (air/land/sea), labeling needs for tracking contingents across borders if applicable, usage of insulation elements (foam/gel/bubble wrap) where necessary, etc., testing protocols related to temperature & shelf life specific validation requirements both pre-shipment & post-shipment based on industry standards such FDA Drug Good Laboratory Practice 21 CFR Part 111 Subpart G, etc., all depending on what is being shipped within each country’s jurisdictions even when dealing with international suppliers & customers alike – In short, a great deal goes into ensuring product integrity throughout its lifecycle before reaching its intended consumer unaffectedly!

Conclusion

Now that you know everything there is to know about the cold chain, it’s time to put your knowledge into action. Nordic Cold Chain Solutions offers a variety of services and products to help you maintain an efficient cold chain.

Contact us today to learn more about how we can help you with your cold chain needs!