Pharmaceutical cold chain management is critical in maintaining the efficacy and safety of medications, vaccines, and other temperature-sensitive products. From manufacturers to healthcare providers, every step in the supply chain must adhere to strict temperature requirements to ensure product quality. Failure to maintain these standards can lead to product spoilage, significant financial losses, and potential patient harm. This article will explore the best practices for handling pharmaceuticals in the cold chain, highlighting essential strategies to maintain compliance, mitigate risks, and protect product integrity.

The Importance of Cold Chain Solutions in the Pharmaceutical Industry

The pharmaceutical industry relies heavily on cold chain logistics to ensure that temperature-sensitive products, such as vaccines and specialty drugs, are delivered optimally. These products must often be stored and transported within specific or ultra-low temperatures for certain biologics. Deviation from these temperature requirements can compromise these products’ potency, safety, and efficacy, leading to significant consequences for patient health.

The pharmaceutical industry relies heavily on cold chain logistics to ensure that temperature-sensitive products, such as vaccines and specialty drugs, are delivered optimally. These products must often be stored and transported within specific or ultra-low temperatures for certain biologics. Deviation from these temperature requirements can compromise these products’ potency, safety, and efficacy, leading to significant consequences for patient health.

Cold chain management goes beyond refrigeration; it involves a complex network of processes, including packaging, transportation, monitoring, and storage, all designed to maintain a controlled environment. Proper execution of these processes is essential for meeting regulatory standards, such as those set by the U.S. Food and Drug Administration (FDA).

Risks Associated with Improper Handling in the Cold Chain

The risks of improper handling in the cold chain are vast. Temperature excursions, or deviations from the required temperature range, are among the most common issues faced during transportation and storage. These can occur due to equipment failure, transit delays, inadequate packaging, or human error. Such incidents can lead to:

- Product spoilage: A single temperature excursion can render a batch of pharmaceuticals useless, resulting in significant financial losses and potential drug shortages.

- Compliance violations: Failing to adhere to cold chain standards can lead to regulatory penalties, recalls, and damage to a company’s reputation.

- Patient safety risks: Ineffective pharmaceuticals can lead to treatment failures, adverse reactions, and increased healthcare costs.

Challenges in Cold Chain Logistics

Managing the cold chain is not without its challenges. The complexity of global supply chains, variable environmental conditions, and the need for real-time data monitoring add layers of difficulty. Companies must navigate issues such as:- Regulatory compliance: Different countries have varying regulations regarding the handling of pharmaceuticals, making global cold chain management particularly challenging.

- Infrastructure limitations: Maintaining consistent temperature control can be especially difficult in regions with limited cold chain infrastructure, increasing the risk of product degradation.

- Environmental factors: Weather conditions, such as extreme heat or cold, can impact maintaining temperature control, especially during transportation.

Best Practices for Handling Pharmaceuticals in the Cold Chain

- Utilize Proper Packaging Materials: Effective cold chain management begins with selecting the right packaging materials. Packaging solutions should provide thermal protection and maintain the required temperature range throughout the journey. Insulated packaging, such as high-performance mailers and phase change materials (PCMs), are commonly used to achieve this.

- Insulated Packaging: Insulated packaging mailers are designed to provide high thermal protection, even in extreme temperatures. These panels can keep products within the required temperature range for extended periods, making them ideal for long-haul shipments or routes with limited access to refrigeration.

- Phase Change Materials (PCMs): PCMs are engineered to maintain precise temperature ranges by absorbing or releasing heat as needed. These materials are used in our gel packs and are particularly useful for pharmaceuticals that require ultra-low temperatures, providing an extra layer of protection during transit.

Implement Real-Time Monitoring and Tracking Technologies

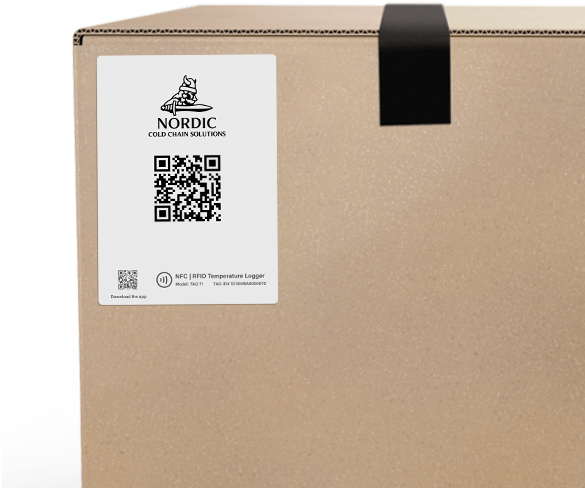

Continuous monitoring of environmental conditions is crucial to maintaining the integrity of temperature-sensitive pharmaceuticals. Real-time tracking technologies, such as data loggers, GPS, and temperature indicators, provide visibility into the conditions within the supply chain. This allows companies to respond quickly to temperature excursions or other issues.

- Data Loggers: These devices record temperature data throughout the transportation process, providing a detailed record of conditions that can be used for quality assurance and regulatory compliance.

- Temperature Indicators: These tools provide immediate visual confirmation of temperature deviations, allowing for quick corrective actions. They are especially useful during last-mile delivery when temperature control can be most vulnerable.

Securing the Cold Chain

Following best practices for handling pharmaceuticals in the cold chain is crucial for maintaining product integrity, meeting regulatory standards, and ensuring patient safety. From proper packaging and real-time monitoring to risk management strategies, each step plays a vital role in the success of cold chain logistics. By prioritizing these practices, pharmaceutical companies can safeguard their products, protect their brand reputation, and improve patient outcomes.

Following best practices for handling pharmaceuticals in the cold chain is crucial for maintaining product integrity, meeting regulatory standards, and ensuring patient safety. From proper packaging and real-time monitoring to risk management strategies, each step plays a vital role in the success of cold chain logistics. By prioritizing these practices, pharmaceutical companies can safeguard their products, protect their brand reputation, and improve patient outcomes.